Erecting a

"One Man Tower"

(this is

not a complete photo page so check back as more pics will be

added)

Firstly

some common sense tips about towers and erecting them

1. Always

wear an approved climbing harness with an attaching

lanyard.

2. Never

allow people to enter the area below where you are

working.

3. If

possible secure a line to the top of the structure in order to tie

yourself off while climbing.

4. Always

use a "utility bag" made of sturdy canvas to carry spanners and

hardware to the working position. On the OMT this can be attached to

the slide carriage where it can be easily accessed once you are in

position to bolt the sections together.

5. Always

wear an approved climbing harness with an attaching

lanyard.

And

finally ALWAYS WEAR AN APPROVED CLIMBING HARNESS WITH AN ATTACHING

LANYARD!

The OMT

was invented to make our hobby a safer place to enjoy - but you must

do your part - never be complacent about the dangers associated with

climbing any structure - a climbing harness only costs a couple of

hundred $$$ - a small price to pay when you consider the possible

alternatives.

----

---- You've

poured your base - stood the base section - fitted the winch/wire and

slide carriage - then you fit the "self erecting jig" to the slide

carriage (pictures show an older version of the slide carriage set

up)

You've

poured your base - stood the base section - fitted the winch/wire and

slide carriage - then you fit the "self erecting jig" to the slide

carriage (pictures show an older version of the slide carriage set

up)

---

--- Now you

stand the next section (the winch can make this a very easy evolution

as the wire can be transferred to the section and winch it into

position) - the slide tracks are now clamped into the cheekplates of

the self erecting jig.

Now you

stand the next section (the winch can make this a very easy evolution

as the wire can be transferred to the section and winch it into

position) - the slide tracks are now clamped into the cheekplates of

the self erecting jig.

---

--- ---

--- And away

it goes - the photos show a section in lift and once it has reached

the top of the standing tower it is simply swivelled over the top and

bolted in position.

The

cheekplates of the self erecting jig are released and the whole

carriage/jig assembly is lowered to attach the next

section.

And away

it goes - the photos show a section in lift and once it has reached

the top of the standing tower it is simply swivelled over the top and

bolted in position.

The

cheekplates of the self erecting jig are released and the whole

carriage/jig assembly is lowered to attach the next

section.

---

--- The pulley

that is attached to the top of the sections must be transferred each

section - and you repeat the exercise until your tower is erected.

One person can easily erect a 15m tower - fit their antenna and be on

air in one day. (Well....one normally active and motivated person

that is - of course there will always be those among us who would not

be able to erect a sand castle on a beach with a bucket.)

The pulley

that is attached to the top of the sections must be transferred each

section - and you repeat the exercise until your tower is erected.

One person can easily erect a 15m tower - fit their antenna and be on

air in one day. (Well....one normally active and motivated person

that is - of course there will always be those among us who would not

be able to erect a sand castle on a beach with a bucket.)

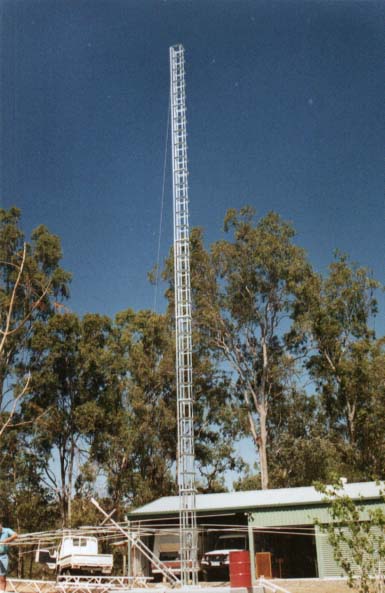

This gives

an idea of the portable nature of the towers - remember this is a

complete 15m FREE STANDING HEAVY DUTY TOWER - and it is shown here on

a pallet as it was being prepared for transport overseas. The 15m One

Man Tower far exceeds the Australian Wind Code (AS1170.2) and was

tested by Facet Engineering Consultants using the standards as laid

down under AS 4100 for steel structures.

This gives

an idea of the portable nature of the towers - remember this is a

complete 15m FREE STANDING HEAVY DUTY TOWER - and it is shown here on

a pallet as it was being prepared for transport overseas. The 15m One

Man Tower far exceeds the Australian Wind Code (AS1170.2) and was

tested by Facet Engineering Consultants using the standards as laid

down under AS 4100 for steel structures.

---

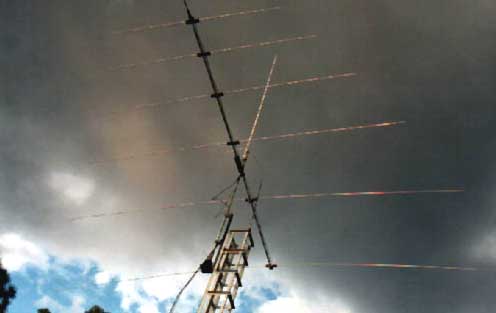

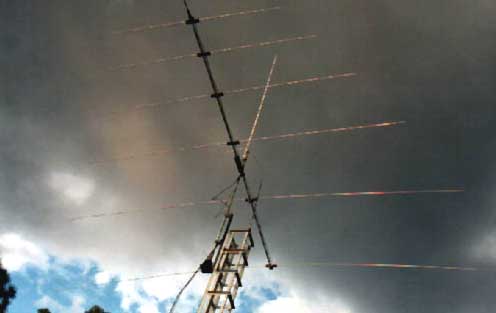

--- Here is a

graphic example of what it is all about - SAFETY, SAFETY AND MORE

SAFETY!!! - a storm is brewing - within a couple of minutes the whole

top 2.5m of the tower including the antenna array is brought close to

the ground out of the most destructive wind forces and the

instalation becomes nothing more than a 12.5m tower - less windload

area presented to the howling wind and a far safer way to have any

antenna instalation.

Here is a

graphic example of what it is all about - SAFETY, SAFETY AND MORE

SAFETY!!! - a storm is brewing - within a couple of minutes the whole

top 2.5m of the tower including the antenna array is brought close to

the ground out of the most destructive wind forces and the

instalation becomes nothing more than a 12.5m tower - less windload

area presented to the howling wind and a far safer way to have any

antenna instalation.

---

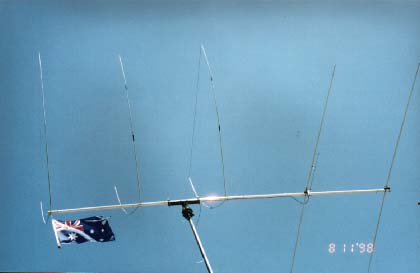

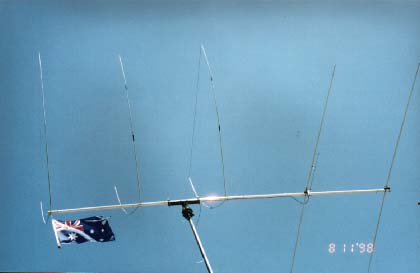

--- Here is a

4 el Delta loop for 10m on the left and on the right is an 8 el duo -

bander with 4 el delta on 10m and 4 el Yagi on 15m

The next

thing is to consider just how easy it is to install and make

adjustments to any antenna array - but consider just what is involved

with very large and very awkward antenna arrays - with any other sort

of tower you are faced with considerable difficulty fitting or

adjusting - with the One Man Tower every experimenters dreams are

fulfilled. You install and make adjustments with your feet planted

firmly on the ground - no need to have a large, clear space to tilt

over the tower - no guys to worry about - and no expensive

"Cherrypicker" hire cost to worry about. No longer do you have to

prevail on the good nature of your friends or family - no longer do

you have to put peoples lives at risk - your One Man Tower gives you

complete control.

EASILY AND

SAFELY!!!

Here is a

4 el Delta loop for 10m on the left and on the right is an 8 el duo -

bander with 4 el delta on 10m and 4 el Yagi on 15m

The next

thing is to consider just how easy it is to install and make

adjustments to any antenna array - but consider just what is involved

with very large and very awkward antenna arrays - with any other sort

of tower you are faced with considerable difficulty fitting or

adjusting - with the One Man Tower every experimenters dreams are

fulfilled. You install and make adjustments with your feet planted

firmly on the ground - no need to have a large, clear space to tilt

over the tower - no guys to worry about - and no expensive

"Cherrypicker" hire cost to worry about. No longer do you have to

prevail on the good nature of your friends or family - no longer do

you have to put peoples lives at risk - your One Man Tower gives you

complete control.

EASILY AND

SAFELY!!!

---

--- A 4 el

Yelta (Yagi/Delta loop hybrid) and a 5 el version - these antennae

were a real enigma - and serious testing is still under way on them -

these babies PERFORM big.

A 4 el

Yelta (Yagi/Delta loop hybrid) and a 5 el version - these antennae

were a real enigma - and serious testing is still under way on them -

these babies PERFORM big.

---

--- The

AEI/OMT "Foundation Special" - a 5el Log Periodic that works superbly

for 10m and 15m - then shown with a duo-band Diamond 520N mounted

above it to give one fantastic "Foundation Licence" station antenna

set up. These LPDA arrays also work well on the 27MHz.

band.

The

AEI/OMT "Foundation Special" - a 5el Log Periodic that works superbly

for 10m and 15m - then shown with a duo-band Diamond 520N mounted

above it to give one fantastic "Foundation Licence" station antenna

set up. These LPDA arrays also work well on the 27MHz.

band.

Adding the

6th element gave working range down to 13MHz. Not the clearest of

shots but it was very dark with a storm approaching. An ideal

situation for the Foundation Licencee who upgrades to Standard or

Advanced licence - simply add the extra boom length and add the 6th

element and phase harness to give the frequency range to

13MHz.

Adding the

6th element gave working range down to 13MHz. Not the clearest of

shots but it was very dark with a storm approaching. An ideal

situation for the Foundation Licencee who upgrades to Standard or

Advanced licence - simply add the extra boom length and add the 6th

element and phase harness to give the frequency range to

13MHz.

---

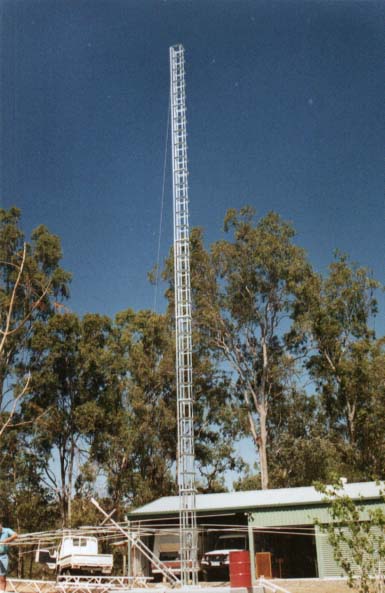

--- Now a

couple of shots of VK4CWT (Harris) antenna arrays - on his 20m tower.

I think Harris might sing some words of praise for the ease with

which he can now install and adjust his antenna arrays

Now a

couple of shots of VK4CWT (Harris) antenna arrays - on his 20m tower.

I think Harris might sing some words of praise for the ease with

which he can now install and adjust his antenna arrays

---

--- And the

1986 instalation at VK4FM (Alan) - a difficult site but the OMT

fitted right in and gave Alan a new dimension for his

hobby.

Many of us

have worked this terrific contributor to our hobby over the years and

I for one hope to work him for many years to come.

And the

1986 instalation at VK4FM (Alan) - a difficult site but the OMT

fitted right in and gave Alan a new dimension for his

hobby.

Many of us

have worked this terrific contributor to our hobby over the years and

I for one hope to work him for many years to come.

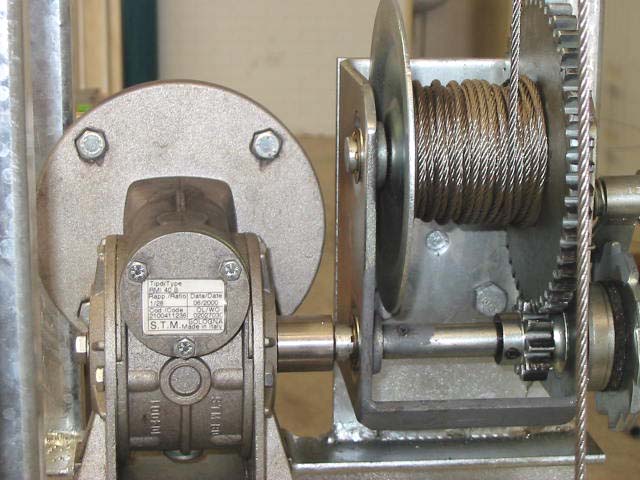

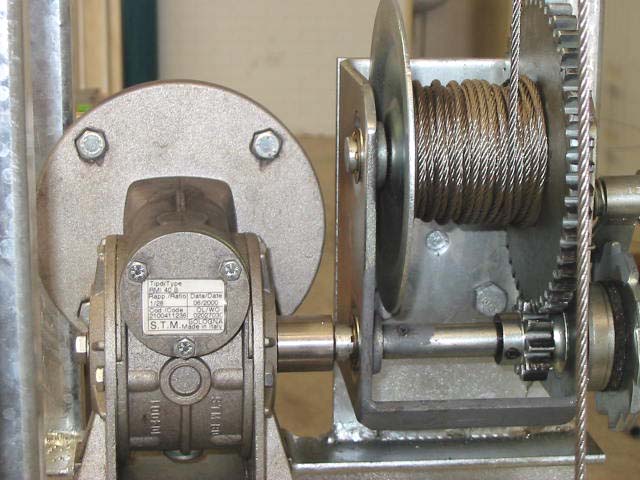

And as of

17th Oct. 2003 Alan has moved into the "luxury" bracket - the manual

winch was removed and replaced with one of the fantastic little 12v

DC motorised versions, taking Alan to an even higher enjoyment

dimension.

These

magnificent little DC motors are only 120w (rated to 12 amps

continuous) and are coupled to a 28:1 reduction gearbox which is

close coupled via a stainless steel shaft to the gear shaft of a 5:1

braking winch.

For the

more elderly, the more feminine, or those simply not caring to crank

on the handle of a manual winch these babies are the

answer.

And as of

17th Oct. 2003 Alan has moved into the "luxury" bracket - the manual

winch was removed and replaced with one of the fantastic little 12v

DC motorised versions, taking Alan to an even higher enjoyment

dimension.

These

magnificent little DC motors are only 120w (rated to 12 amps

continuous) and are coupled to a 28:1 reduction gearbox which is

close coupled via a stainless steel shaft to the gear shaft of a 5:1

braking winch.

For the

more elderly, the more feminine, or those simply not caring to crank

on the handle of a manual winch these babies are the

answer.

The tower

of Greg - VK4AML - originally built for a great old ham (VK4VI -sk)

in 1986 and modified by Greg with a new slide carriage/rotator mount

strongback from todays versions. An "old-timer" still doing a great

job.

Greg shows

just what is possible with some thought and effort.

The tower

of Greg - VK4AML - originally built for a great old ham (VK4VI -sk)

in 1986 and modified by Greg with a new slide carriage/rotator mount

strongback from todays versions. An "old-timer" still doing a great

job.

Greg shows

just what is possible with some thought and effort.

.........

......... Here is

Bob - VK4CPM - with his shiny new 20m tower. Antenna is 9el HF (13 -

30MHz.) Log Periodic made by ATN.

Note here

how the antenna strongback/rotator mount tilts outward to facilitate

loading the antenna onto the mast. Make no mistake this is a large

antenna that takes a bit of handling - ask Bob how easy it was to

install compared to the previous tower he had it on. There is a

picture of it on my homepage with the antenna fully

raised.

Here is

Bob - VK4CPM - with his shiny new 20m tower. Antenna is 9el HF (13 -

30MHz.) Log Periodic made by ATN.

Note here

how the antenna strongback/rotator mount tilts outward to facilitate

loading the antenna onto the mast. Make no mistake this is a large

antenna that takes a bit of handling - ask Bob how easy it was to

install compared to the previous tower he had it on. There is a

picture of it on my homepage with the antenna fully

raised.

Here is

VK4KAD - Ian with John VK4JB erecting a 20m tower. If you saw a red

200l drum in the photos of Bob Becks tower and wondered what it was

for - well wonder no longer. The drum is used to rest the sections on

while the self erecting jig is located at the bottom of the section

being raised - this allows the section to turn into position over the

standing section.

(PS. John

does not have a deformity - he sucked in his gut for the pic hi

hi)

Here is

VK4KAD - Ian with John VK4JB erecting a 20m tower. If you saw a red

200l drum in the photos of Bob Becks tower and wondered what it was

for - well wonder no longer. The drum is used to rest the sections on

while the self erecting jig is located at the bottom of the section

being raised - this allows the section to turn into position over the

standing section.

(PS. John

does not have a deformity - he sucked in his gut for the pic hi

hi)

In spite

of "Murphy" nagging over my shoulder all day the tower was up and the

cold beer enjoyed by 1700hrs (after a slow and tardy start) - a nasty

storm was about to hit. VK4TB and his lovely partner came into shot

with Ian.

In spite

of "Murphy" nagging over my shoulder all day the tower was up and the

cold beer enjoyed by 1700hrs (after a slow and tardy start) - a nasty

storm was about to hit. VK4TB and his lovely partner came into shot

with Ian.

Ray VK2VA

the "mountin' man" from bushranger country - 17.5m at Walcha NSW. I

must say one gets a fantastic view of the beautiful little town of

Walcha from the top of Rays tower - and not a bad view from inside

his shack either.

Listen for

a big noise from this bloke once he hoists up his Force 12 multi-band

beam.

Hams

around the world have bought and are using the One Man Tower - sure

there have been some minor glitches, and there will probably be some

more as time goes by - but ever continuing research and development

makes the One Man Tower the most sought after tower in the world.

Now in its

Mk. 9 version the towers offer a level of user friendliness that

other manufacturers wish they had.

20 years

in service and still going strong.

Late

addition - here are some more descriptive photos of the key to the

One Man Tower - the simple but super effective slide carriage system

(warning it is subject to a pending patent and all material is

copyright of Kevin D. Peacock)

Ray VK2VA

the "mountin' man" from bushranger country - 17.5m at Walcha NSW. I

must say one gets a fantastic view of the beautiful little town of

Walcha from the top of Rays tower - and not a bad view from inside

his shack either.

Listen for

a big noise from this bloke once he hoists up his Force 12 multi-band

beam.

Hams

around the world have bought and are using the One Man Tower - sure

there have been some minor glitches, and there will probably be some

more as time goes by - but ever continuing research and development

makes the One Man Tower the most sought after tower in the world.

Now in its

Mk. 9 version the towers offer a level of user friendliness that

other manufacturers wish they had.

20 years

in service and still going strong.

Late

addition - here are some more descriptive photos of the key to the

One Man Tower - the simple but super effective slide carriage system

(warning it is subject to a pending patent and all material is

copyright of Kevin D. Peacock)

For the

purpose of this exercise I am using the OMT Demo trailer to

demonstrate the erecting of the OMT - and the tray of my little truck

will serve as the ground in front of the tower;-)

For the

purpose of this exercise I am using the OMT Demo trailer to

demonstrate the erecting of the OMT - and the tray of my little truck

will serve as the ground in front of the tower;-)

Here are

the two sections I will use in this demo. The base section is stood

up - you would of course position it over the hold-down bolts that

you cast into your base pad footing - taking care not to damage the

threads.

Here are

the two sections I will use in this demo. The base section is stood

up - you would of course position it over the hold-down bolts that

you cast into your base pad footing - taking care not to damage the

threads.

On the

demo trailer four bolts suffice - in real life you will secure the

section with eight hold-down bolts.

On the

demo trailer four bolts suffice - in real life you will secure the

section with eight hold-down bolts.

Then you

will fit your winch and the electric motor if you have opted for it.

Load the wire onto the winch - under tension BUT DO NOT WRAP IT

AROUND GLOVED HANDS AND LET IT SLIDE THROUGH YOUR HAND AS THIS WILL

PROMOTE ONE SIDE OF THE WIRE AHEAD OF THE OTHER AND IT WILL KINK. The

wire must be allowed to swivel as it loads.

Then you

will fit your winch and the electric motor if you have opted for it.

Load the wire onto the winch - under tension BUT DO NOT WRAP IT

AROUND GLOVED HANDS AND LET IT SLIDE THROUGH YOUR HAND AS THIS WILL

PROMOTE ONE SIDE OF THE WIRE AHEAD OF THE OTHER AND IT WILL KINK. The

wire must be allowed to swivel as it loads.

Fit the

pulley to the top of the section at the hole provided. The sheave can

be removed and refitted after you place the wire inside. Then run the

wire down the outside of the tower and attach it to the slide

carriage....

Fit the

pulley to the top of the section at the hole provided. The sheave can

be removed and refitted after you place the wire inside. Then run the

wire down the outside of the tower and attach it to the slide

carriage....

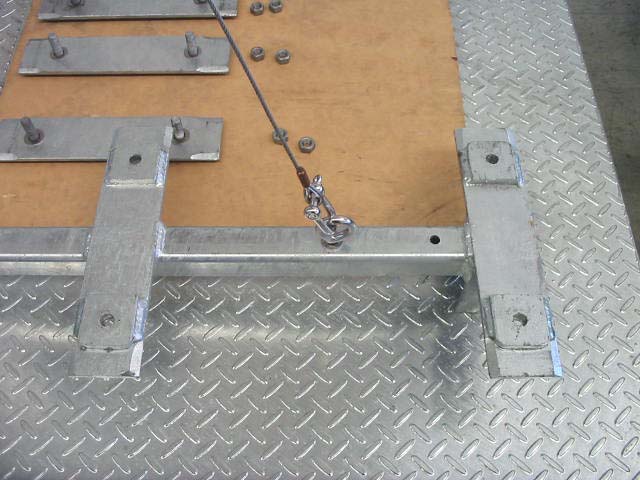

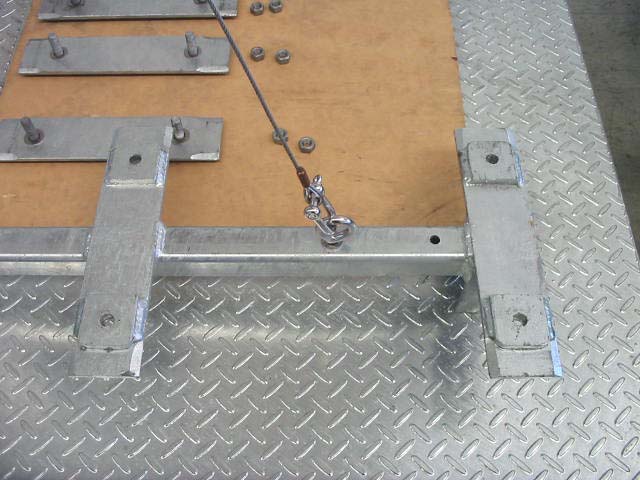

Which you

have laid out ready at the foot of the tower. Note the stainless

steel eyebolt - it must be positioned in the second hole from the top

of the slide carriage for the erection process. (hmmm that was not

intended to sound like that)

Which you

have laid out ready at the foot of the tower. Note the stainless

steel eyebolt - it must be positioned in the second hole from the top

of the slide carriage for the erection process. (hmmm that was not

intended to sound like that)

Attach the

wire to the eye bolt.

Attach the

wire to the eye bolt.

Raise the

slide carriage using your winch and attach it to the slide tracks

using the three cheek plates with matching bevels.

Raise the

slide carriage using your winch and attach it to the slide tracks

using the three cheek plates with matching bevels.

Next make

ready the self erecting jig socket.

Next make

ready the self erecting jig socket.

Place the

bottom of the socket into the lower position of the slide carriage -

insert bolt and secure with nut.

Place the

bottom of the socket into the lower position of the slide carriage -

insert bolt and secure with nut.

Raise the

top of the socket and secure it in position at the top of the slide

carriage.

Raise the

top of the socket and secure it in position at the top of the slide

carriage.

Now you

can test the functioning of the slide carriage as there will be

enough weight now to make the brake work on the braking winch.

Wind it up

and down a few times to get a feel for it and to check that the slide

tracks have not been knocked from their factory settings during

transit.

If they

have you will need to fine tune them so that the slide carriage

travels smoothly along the tracks.

It is a

good idea to actually test the slide carriage on the sections when

they are first delivered and laying on the ground - you will be able

to detect any tight spots and deal with them far easier than when you

have them 40' off the ground.

Now you

can test the functioning of the slide carriage as there will be

enough weight now to make the brake work on the braking winch.

Wind it up

and down a few times to get a feel for it and to check that the slide

tracks have not been knocked from their factory settings during

transit.

If they

have you will need to fine tune them so that the slide carriage

travels smoothly along the tracks.

It is a

good idea to actually test the slide carriage on the sections when

they are first delivered and laying on the ground - you will be able

to detect any tight spots and deal with them far easier than when you

have them 40' off the ground.

The moment

of truth draws near - bring the self erecting jig to the tower base -

note that the cheek plates have no beveled edges. Also you will note

that the spacer is only 5mm - this will give enough friction clamping

force to hold the sections as they are raised into

position.

The moment

of truth draws near - bring the self erecting jig to the tower base -

note that the cheek plates have no beveled edges. Also you will note

that the spacer is only 5mm - this will give enough friction clamping

force to hold the sections as they are raised into

position.

Insert the

slewing pipe stem of the self erecting jig into the slewing slew

tubes of the socket, check that the jig slews easily in the sockets -

DO NOT USE GREASE.

Insert the

slewing pipe stem of the self erecting jig into the slewing slew

tubes of the socket, check that the jig slews easily in the sockets -

DO NOT USE GREASE.

Stand the

next section and bring it to the cheek plates of the self erecting

jig.

Stand the

next section and bring it to the cheek plates of the self erecting

jig.

Clamp the

section into the self erecting jig - the cheek plates will clamp

tightly to the slide tracks - the top cheek plate only needs firm

finger tight but the lower should be taken up sensibly with a spanner

- they do not need to be tightened excessively.

Once you

have the section clamped up, raise it approx 1m off the ground. You

will now need to place an empty 200lt drum or similar under the foot

of the section - some wood may be required to pack up the right

amount.

This must

be done in order to let the self erecting jig slide back down to the

bottom of the section where it is to be clamped for the final lifting

of each new section - think about it and you will understand why this

must be done.

Clamp the

section into the self erecting jig - the cheek plates will clamp

tightly to the slide tracks - the top cheek plate only needs firm

finger tight but the lower should be taken up sensibly with a spanner

- they do not need to be tightened excessively.

Once you

have the section clamped up, raise it approx 1m off the ground. You

will now need to place an empty 200lt drum or similar under the foot

of the section - some wood may be required to pack up the right

amount.

This must

be done in order to let the self erecting jig slide back down to the

bottom of the section where it is to be clamped for the final lifting

of each new section - think about it and you will understand why this

must be done.

This is

how the self erecting jig lower cheek plate and the bottom of the

slide track of each new section should be mated.

This is

how the self erecting jig lower cheek plate and the bottom of the

slide track of each new section should be mated.

The

section can now be taken to the top of the tower.

The

section can now be taken to the top of the tower.

Raise it

until it is clear of the top of the standing tower

sections.

Raise it

until it is clear of the top of the standing tower

sections.

And rotate

it into position over the top of the standing section.

Unfortunately I ran out of room in the factory and

could not fully rotate it - so be patient with me and I will continue

the story when I take the trailer outside - I might even wait until I

take it to the next Hamfest and finish the shoot there.

In the

meantime - thank you for joining me and the worlds best Ham Radio

tower - we enjoyed having you.

And rotate

it into position over the top of the standing section.

Unfortunately I ran out of room in the factory and

could not fully rotate it - so be patient with me and I will continue

the story when I take the trailer outside - I might even wait until I

take it to the next Hamfest and finish the shoot there.

In the

meantime - thank you for joining me and the worlds best Ham Radio

tower - we enjoyed having you.

And here

is the demo tower fully deployed - one of the fantastic side benefits

is that it also serves as a portable station for field days - here

VK4MR is working stations from "Jollies Lookout" to the Northwest of

Brisbane City.

Antennas

used here were a 17el Logcell yagi on 2m and a 17el Logcell yagi on

70cm. We had a fantastic area of working coverage and the magnificent

bushland setting and view more than compensated for the miserably

poor response from our fellow hams on UHF/VHF (we made only 21

contacts in the full days working - a sad indictment of the interest

in Amateur radio unfortunately)

During the

time we spent at the location we were continually approached by

curious tourists and sightseers - at least THEY were interested in

Amateur radio hi hi!!!!!!

73s

and stay well.

Safe radio

doesn't mean sticking a condom over your microphone - although when I

listen to some of the airwaves content nowadays it may not be such a

bad idea - without CW it's just CB hi hi................

Home

email -

aeitower@spin.net.au

Mob. phone

0414 254 080

Rate

this site @ dxzone.com

And here

is the demo tower fully deployed - one of the fantastic side benefits

is that it also serves as a portable station for field days - here

VK4MR is working stations from "Jollies Lookout" to the Northwest of

Brisbane City.

Antennas

used here were a 17el Logcell yagi on 2m and a 17el Logcell yagi on

70cm. We had a fantastic area of working coverage and the magnificent

bushland setting and view more than compensated for the miserably

poor response from our fellow hams on UHF/VHF (we made only 21

contacts in the full days working - a sad indictment of the interest

in Amateur radio unfortunately)

During the

time we spent at the location we were continually approached by

curious tourists and sightseers - at least THEY were interested in

Amateur radio hi hi!!!!!!

73s

and stay well.

Safe radio

doesn't mean sticking a condom over your microphone - although when I

listen to some of the airwaves content nowadays it may not be such a

bad idea - without CW it's just CB hi hi................

Home

email -

aeitower@spin.net.au

Mob. phone

0414 254 080

Rate

this site @ dxzone.com

----

----

----

----

---

---

---

--- ---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

.........

.........